pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

Plywoood

Complete Guide to Plywood Grades and How to Choose the Best for Your Project

Table of Contents for the Article

Choosing the right plywood grade is essential for the success of any construction or carpentry project. In this comprehensive guide, we will explain everything you need to know about the different plywood grades, their characteristics, and specific applications, so you can make the best decision according to your needs.

Plywood is a composite material made by bonding multiple layers of wood veneer with the grain of each layer oriented perpendicular to the next. This cross-grain construction provides exceptional strength and superior dimensional stability compared to solid wood.

The manufacturing process involves peeling logs to obtain thin sheets, which are then dried, graded by quality, and assembled using specialized adhesives under controlled pressure and temperature. This process directly determines the final plywood grade of the product.

The grading system uses letters (A, B, C, D) and numerical combinations to indicate the quality of the plywood faces. The first character represents the front face, while the second indicates the back face. For example, B/BB means the front face is grade B and the back face is grade BB.

Grade A represents the highest quality in softwood plywood. This classification guarantees completely smooth surfaces, free of knots, holes, or visible imperfections. It is ideal for applications where appearance is critical, such as fine furniture and high-end decorative projects.

Grade B allows minor imperfections and sound knots smaller than 25mm in diameter. Repairs with wood patches are acceptable, maintaining a relatively smooth surface. This grade offers an excellent balance between aesthetic quality and price.

Grade C accepts knots up to 40mm in diameter and some minor separations. Although it has more visible defects, it maintains structural integrity. It is commonly used in applications where appearance is not a priority but structural strength is required.

Grade D is the most economical, allowing large knots, holes, and significant defects. Although its appearance is limited, it retains the necessary structural properties for hidden applications or substructures.

Grade A1 in hardwood represents absolute excellence, featuring uniform grain patterns and perfectly sanded surfaces. It is the premium choice for luxury cabinetry, musical instruments, and projects requiring exceptional finishes.

Intermediate grades such as A2 and B1 offer high quality with minor natural wood variations. Grade BB allows minor repaired defects, while CC is an economical option for structural applications where appearance is secondary.

The AB grade combines a high-quality face (A) with a good-quality back (B), optimizing costs when only one side will be visible. It is perfect for decorative panels, built-in cabinets, and similar applications.

The BR grade includes special treatments to resist moisture, maintaining structural integrity in environments with occasional water exposure. It is ideal for kitchens, bathrooms, and semi-outdoor areas.

Grade BB is an excellent option for general use, allowing small, sound knots. It offers good appearance and structural strength, making it versatile for many decorative and functional applications.

Grade CC is the most economical option while maintaining structural integrity. Although it shows visible defects, it is perfect for flooring, concealed ceilings, and structures where appearance is not relevant.

Grade A is characterized by flawless surfaces, uniform grain patterns, and a total absence of defects. It requires more rigorous manufacturing processes and carefully selected wood, which is reflected in its premium price.

In many applications, specifying Grade A represents an unnecessary additional cost. For substructures, flooring bases, or projects where coatings will be applied, lower grades provide the same functionality at a lower cost.

Grades B/BB offer an excellent quality-to-price ratio, providing good appearance and structural strength. They are ideal for furniture, interior paneling, and projects that seek to balance aesthetics and economy.

B/BB plywood offers an attractive appearance with minor natural imperfections that many find desirable, adding character to projects while keeping costs under control.

Structurally, Grade B/BB provides the same mechanical properties as Grade A, including bending, tensile, and compressive strength. The difference lies solely in surface appearance.

High-quality B/BB products strictly comply with international standards such as EN 636-2, ensuring reliable performance in both structural and decorative applications.

For indoor applications such as furniture, decorative panels, and wall coverings, Grade B/BB delivers excellent results. Higher grades are only justified in luxury projects where aesthetic perfection is paramount.

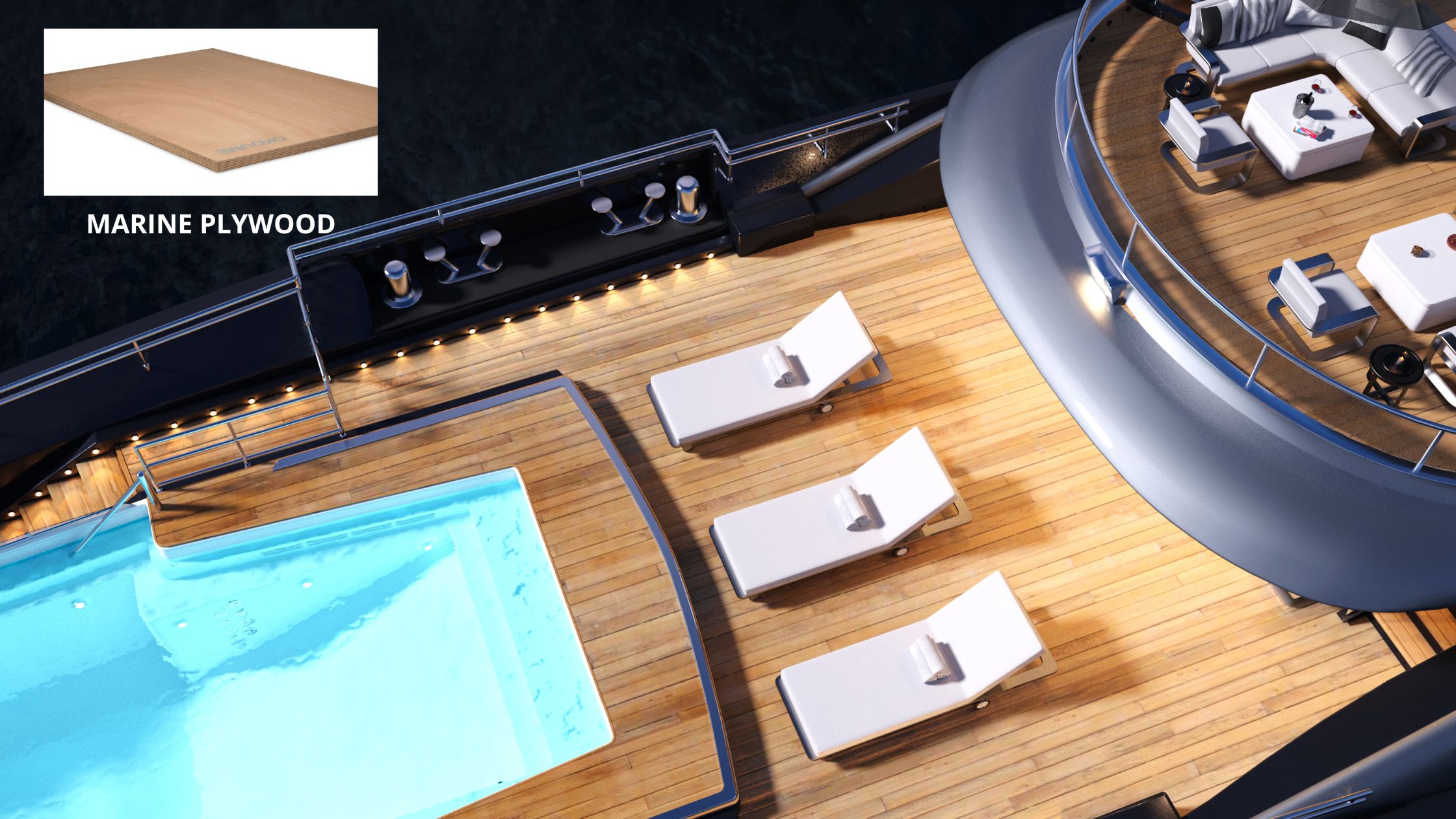

In outdoor applications, weather resistance is more important than flawless appearance. B/BB marine plywood offers exceptional durability for boats and exposed structures.

For decorative projects, consider whether the minor imperfections of Grade B/BB complement the desired style. Many contemporary designs embrace the natural beauty of wood with its characteristic variations.

The Exterior rating guarantees permanent weather resistance through the use of high-quality waterproof adhesives. It is essential for applications with direct exposure to climatic elements.

Exposure 2 allows temporary exposure to moisture during construction but requires protection for permanent outdoor use. It is common in residential construction as temporary sheathing.

The Interior rating uses adhesives that may fail with excessive moisture, limiting its use to controlled environments. It offers excellent performance and economy for indoor applications.

Construction plywood such as CDX prioritizes structural strength and economy over appearance. It uses softwoods and is optimized for structural loads in residential and commercial construction.

Project plywood emphasizes appearance and workability. Species like Baltic birch offer attractive grain patterns and smooth surfaces ideal for furniture and fine carpentry.

Sanded plywood features surfaces prepared for direct finishing, eliminating the need for additional preparation work. Grades range from A to D, allowing selection of the appropriate quality for the specific application.

Although not traditional plywood, OSB (Oriented Strand Board) provides economical structural strength for substructures, flooring, and applications where appearance is not critical.

Eco-friendly plywood uses formaldehyde-free adhesives and certified wood, meeting growing sustainability demands without compromising performance or durability.

Pressure-treated plywood incorporates chemical preservatives that prevent degradation from insects and fungi, significantly extending its service life in demanding exterior applications.

CDX is the standard for exterior sheathing during construction, offering temporary weather resistance while permanent finishes are completed. Its C/D grade balances cost and functionality.

Choosing stainless steel hardware and appropriate protective systems is crucial to maximize the performance of exterior plywood, regardless of its quality grade.

Machining plywood generates dust that can be harmful to respiratory health. Always use dust extraction systems and appropriate personal protective equipment.

Some traditional adhesives contain formaldehyde and other volatile compounds. Choose plywood with low-emission or formaldehyde-free adhesives for sensitive indoor environments.

Selecting the plywood grade requires balancing multiple factors: aesthetic requirements, structural loads, environmental exposure, and available budget. Analyze each factor according to your specific application.

Grade | Main Characteristics | Common Uses |

A | Smooth surface, minimal defects, high quality. | Furniture, cabinetry, high-end woodworking, decorative applications, architectural projects. |

B | Solid surface with small defects, suitable for painting. | Subfloors, sheathing, structural panels, exterior siding, interior wall paneling. |

C | Visible defects such as knots, cracks, and patches. | Roof decking, temporary structures, DIY projects, non-structural applications. |

D | More pronounced knots, cracks, and patches. | Temporary construction, utilitarian purposes, packaging, pallets, shed construction. |

Grade | Furniture | Construction | Exterior | Relative Price |

A | Excellent | Unnecessary | Good | High |

B/BB | Very Good | Good | Very Good | Medium |

C/CC | Limited | Excellent | Fair | Economical |

D | No | Structural | No | Very Economical |

Physically inspect the sheets whenever possible, verify quality certifications, and consider suppliers with proven experience. The plywood grade should match your exact specifications.

Avoid over-specifying unnecessary quality or under-specifying for critical applications. Not all plywood grades are suitable for every use, and false economy can be costly in the long run.

At Pico Plywood, we offer a wide range of products classified according to rigorous international standards:

Product | Classification | Standard |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB, BB/CP, CP/CP | EN 636-2 | |

B/B or B/BB | BS 1088 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB or BB/BB | EN 636-2 | |

B/BB | EN 636-2 |

For furniture, Grade B/BB offers an excellent balance between appearance and cost. Only specify Grade A if you require absolute perfection for luxury finishes.

CDX indicates Grade C on the front face, Grade D on the back face, with adhesive X (Exposure 1) for moisture resistance. It is the standard for structural construction.

We do not recommend interior plywood for permanent outdoor use, as adhesives may fail with prolonged moisture exposure. Use Exterior or Exposure 1 ratings instead.

Grade D and combinations like CC/DD are the most economical, maintaining structural integrity for hidden applications.

B/BB means a Grade B front face and Grade BB back face, allowing minor repaired imperfections. It is very popular for general use due to its versatility.

Suitability for exterior use depends more on the adhesive rating (Exterior, Exposure 1, Exposure 2, Interior) than on the surface grade. Check both specifications.

The lifespan of plywood varies depending on grade, wood species, adhesives used, and exposure conditions. With proper protection, it can last decades in appropriate applications.

Selecting the appropriate plywood grade is crucial for the success of your project. Carefully consider factors such as required appearance, environmental exposure, structural loads, and available budget. B/BB grades offer excellent versatility for most applications, while premium grades are reserved for cases where aesthetic perfection is essential.

At Pico Plywood, our technical team is available to assist you in selecting the optimal grade according to your specific needs. Our wide range of certified products ensures you will find the perfect solution for your project, balancing quality, performance, and economic value.

Remember that investing in the correct plywood grade from the start can save you time, money, and future frustrations, ensuring professional results that last over time.

pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Strictly necessary cookies must always be enabled so that we can save your cookie setting preferences.

If you deactivate this cookie we will not be able to save your preferences. This means that each time you visit this website you will have to activate or deactivate cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable strictly necessary cookies first so we can save your preferences!