pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

Plywoood

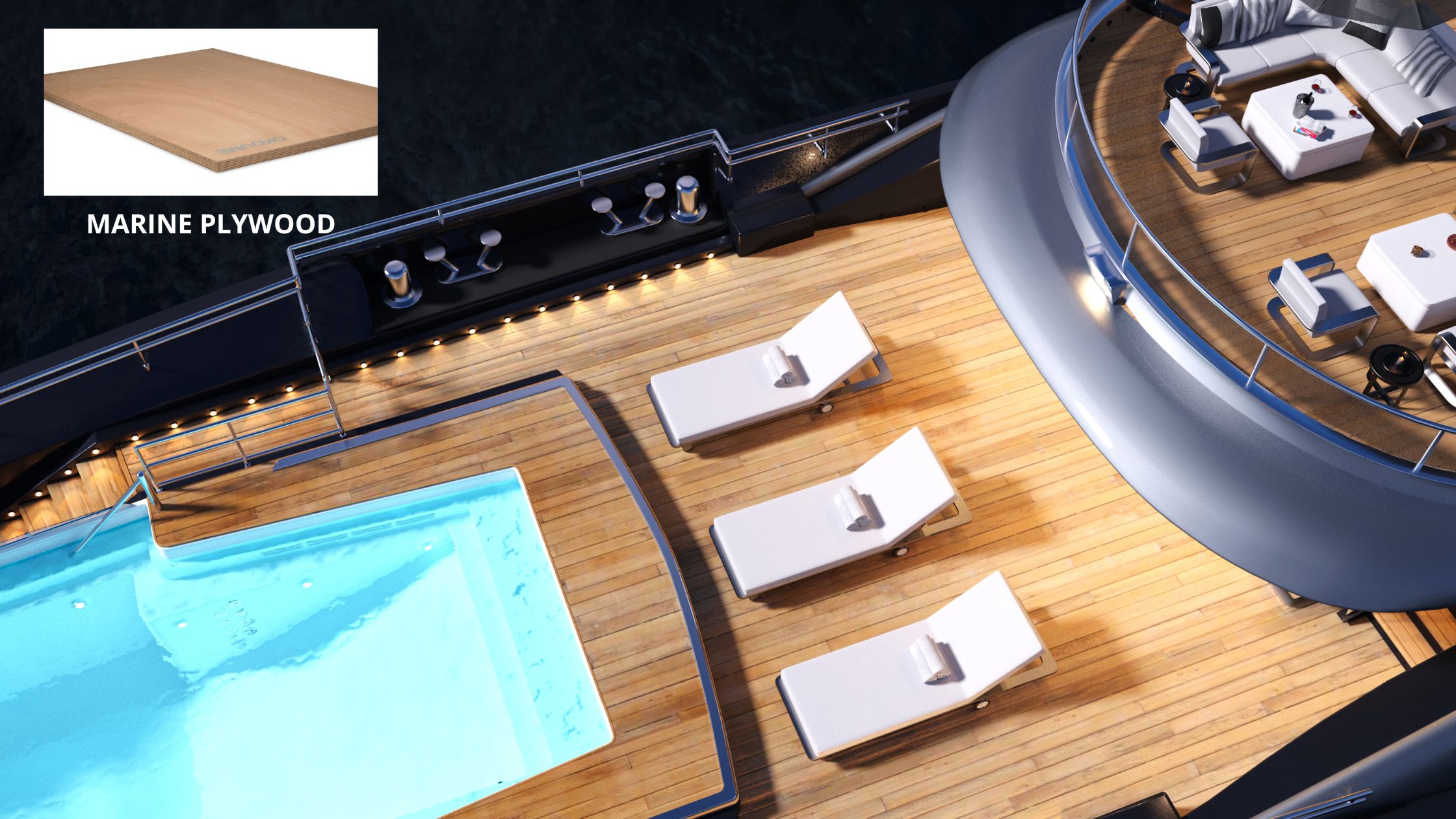

Discover the best plywood for boat decks

Table of Contents for the Article

When it comes to building or renovating your boat deck, choosing the right boat decking plywood is crucial for ensuring safety, durability, and performance on the water. This comprehensive guide will help you understand everything about plywood for boat decking, from material selection to installation and maintenance.

Marine plywood represents the gold standard for boat deck plywood applications. Unlike standard plywood, marine-grade materials are specifically engineered to withstand the harsh marine environment, making them the preferred choice for serious boaters and shipbuilders.

The primary reason marine plywood boat decking is so popular lies in its construction. This specialized plywood uses waterproof adhesives and high-quality veneers with minimal voids, creating a material that can resist moisture penetration and maintain structural integrity even when exposed to constant humidity and occasional water exposure.

The key differences between marine plywood and standard plywood are significant when considering plywood for boat deck applications:

Construction Quality: Marine plywood uses only high-grade veneers with no gaps or voids in the inner layers, while standard plywood may contain patches and gaps that can compromise water resistance.

Adhesive Type: Marine-grade materials utilize waterproof phenolic or resorcinol adhesives that won’t fail in wet conditions, unlike the water-resistant adhesives used in standard plywood.

Wood Species: Best plywood for boat deck applications typically uses species like Okoume, Douglas Fir, or Baltic Birch, which offer superior strength-to-weight ratios and natural moisture resistance.

Quality Control: Marine plywood undergoes stricter quality control processes, ensuring consistent thickness, surface quality, and structural integrity throughout each sheet.

The most critical advantage of using proper boat deck plywood is its superior resistance to water and moisture. The waterproof adhesives and quality construction prevent delamination and rot, even in constantly damp conditions.

Marine plywood maintains dimensional stability under varying humidity conditions, preventing warping, cupping, or twisting that could compromise your deck’s integrity. This stability is essential for pontoon boat plywood decking and other applications where the deck experiences varying loads and conditions.

The consistent construction and high-quality materials provide excellent structural strength, ensuring your deck can safely support passengers, equipment, and dynamic loads encountered during navigation.

Selecting the right type of plywood for boat decking depends on your specific needs, budget, and boat type. Here are the most common options available:

Okoume marine plywood stands out as one of the best plywood for boat deck applications due to its exceptional properties. This African hardwood offers an excellent strength-to-weight ratio, making it ideal for performance boats where weight savings matter.

Okoume’s light color and attractive grain pattern also make it popular for visible deck applications. Its natural oils provide additional moisture resistance, and it accepts stains and finishes beautifully. However, Okoume typically comes at a premium price point compared to other marine plywood options.

Baltic birch represents another excellent choice for boat decking plywood. This material features numerous thin plies (typically 13 layers in 3/4″ thickness) that create exceptional strength and stability. The void-free construction and consistent quality make it reliable for marine applications.

While not always labeled as «marine grade,» high-quality Baltic birch uses waterproof adhesives and offers performance comparable to marine plywood at a more affordable price point. It’s particularly popular for best plywood for jon boat deck applications where budget considerations are important.

Understanding the difference between ACX and CDX plywood is crucial when considering cdx plywood for boat deck applications:

ACX Plywood: Features one smooth, sanded face (A grade) and one solid face with possible patches (C grade). The X designation indicates waterproof adhesive, making it suitable for marine applications with proper sealing.

CDX Plywood: Has rougher surfaces on both sides with possible knots and patches. While the X indicates waterproof adhesive, the lower surface quality makes it less ideal for visible deck applications.

For most boat deck plywood applications, ACX provides a better balance of cost and performance, especially when the smooth side will be visible or require finishing.

While plywood remains popular, several plywood alternative for boat decking options exist:

Fiberglass Panels: Offer complete waterproofing but can be more expensive and require specialized installation skills.

Composite Decking: Provides excellent durability and low maintenance but may lack the structural strength needed for load-bearing applications.

Aluminum Sheets: Extremely durable and lightweight but can be noisy and may require additional insulation for comfort.

Selecting the correct boat deck plywood thickness is critical for ensuring adequate strength while minimizing weight. The right thickness depends on several factors including boat size, intended use, and structural support.

For best plywood for jon boat deck applications, 1/2″ (12mm) marine plywood typically provides adequate strength for boats up to 16 feet. The key considerations include:

What size plywood for jon boat deck ultimately depends on your specific boat design, but 1/2″ represents the minimum thickness for most applications, while 5/8″ provides additional safety margin.

Mid-size recreational boats typically require 5/8″ to 3/4″ boat deck plywood thickness. These boats experience higher loads from passengers, equipment, and rigging forces (in sailboats).

The increased thickness provides:

Pontoon boat plywood decking and larger vessels often require 3/4″ to 1″ thickness due to wider frame spacing and higher load requirements. The larger deck areas and multiple passenger capacity demand robust construction.

When determining what plywood for boat deck thickness to use, consider these critical factors:

Structural Requirements: Calculate the expected loads and frame spacing to ensure adequate bending strength and stiffness.

Weight Budget: Every pound of decking affects boat performance, fuel consumption, and handling characteristics.

Installation Complexity: Thicker materials are harder to bend around curves and may require specialized tools for cutting and fastening.

Cost Considerations: Material costs increase significantly with thickness, so avoid over-building while maintaining safety margins.

Proper installation of boat decking plywood requires careful planning and attention to detail. Following these steps ensures a professional result that will provide years of reliable service.

Before installing your plywood boat deck, thorough surface preparation is essential:

Remove Old Decking: Carefully remove existing deck material, taking note of any structural issues or frame damage that needs repair.

Inspect Framework: Check all support structures for rot, corrosion, or damage. Replace or repair any compromised framing before proceeding.

Clean Surfaces: Remove all debris, old adhesive, and loose material. The frame surfaces should be clean and dry for optimal adhesion.

Check for Level: Ensure the framework is properly aligned and level. Address any high or low spots that could cause stress concentrations in the new decking.

Accurate cutting and fitting are crucial for professional results:

Create Templates: For complex shapes, create cardboard templates before cutting expensive marine plywood boat decking materials.

Plan Sheet Layout: Minimize joints and ensure they fall over structural supports. Consider grain direction and appearance matching for visible surfaces.

Cutting Techniques: Use sharp, fine-tooth blades to prevent splintering. Support the material properly during cutting to ensure clean, square edges.

Test Fit: Always test-fit pieces before final installation. Mark and trim as necessary for perfect fit.

Sealing plywood for boat deck applications requires multiple steps:

Edge Sealing: Apply marine-grade sealant to all cut edges immediately after cutting. This prevents moisture intrusion through exposed end grain.

Surface Preparation: Lightly sand all surfaces with 120-grit sandpaper to improve adhesion of sealants and finishes.

Prime Application: Apply a high-quality marine primer to all surfaces, paying special attention to joints and edges.

Waterproof Barrier: Consider applying a moisture barrier membrane over the plywood before final finishing, especially in high-exposure areas.

Proper fastening ensures long-term durability:

Fastener Selection: Use marine-grade stainless steel or bronze screws appropriate for your plywood thickness. Avoid steel fasteners that can cause staining and corrosion.

Fastening Pattern: Follow manufacturer recommendations for fastener spacing, typically 6-8 inches on center along edges and 12 inches on center in the field.

Countersinking: Properly countersink all fasteners to prevent water collection and ensure smooth surfaces for finishing.

Final Sealing: Apply final coats of marine varnish, paint, or other protective finish according to manufacturer specifications.

Proper maintenance extends the life of your boat deck plywood and ensures continued safety and performance. Regular care prevents minor issues from becoming expensive replacements.

Regular Inspection: Examine your deck regularly for signs of wear, damage, or water intrusion. Early detection prevents major problems.

Cleaning Routine: Clean the deck regularly with appropriate marine cleaners. Avoid harsh chemicals that can damage protective finishes.

Immediate Repairs: Address any damage immediately. Small scratches or dings can quickly become major problems if water penetrates the protective finish.

Proper Ventilation: Ensure adequate air circulation around and under the deck to prevent moisture buildup and promote drying.

Penetrating Sealers: These products soak into the wood fibers, providing deep protection while maintaining the natural appearance.

Film-Forming Finishes: Varnishes and polyurethanes create a protective barrier on the surface but require more maintenance as they can crack and peel.

Epoxy Coatings: Provide excellent protection and can be combined with fiberglass over plywood boat deck systems for maximum durability.

Marine Paints: Offer good protection and allow for color customization, but may require more frequent reapplication than clear finishes.

Replace boat deck plywood when you notice:

Don’t wait until damage becomes extensive, as underlying structural damage can be much more expensive to repair.

The best plywood for boat deck applications is marine-grade plywood made from Okoume or similar hardwood species. Look for void-free construction with waterproof adhesives. For budget-conscious projects, high-quality ACX plywood with proper sealing can provide good performance.

For small boats and what type of plywood for boat deck applications, 1/2″ marine plywood is typically adequate for boats under 16 feet with proper framing support. Larger or heavily loaded boats should use 5/8″ to 3/4″ thickness.

Marine plywood is water-resistant, not waterproof. While the adhesives won’t fail when wet, the wood itself can absorb moisture if not properly sealed. Always apply appropriate sealers and finishes for complete waterproofing plywood boat deck applications.

CDX plywood for boat deck can be used in non-critical applications with proper sealing, but it’s not recommended for primary structural decking. The rough surfaces and potential voids make it less suitable than marine-grade alternatives.

Fiberglassing plywood boat deck provides excellent protection and can significantly extend deck life. This technique is especially recommended for high-wear areas or when maximum durability is required. However, it adds weight and complexity to the installation process.

Selecting the right boat decking plywood requires balancing several factors:

Material Quality: Invest in proper marine-grade plywood or high-quality alternatives. The initial cost savings of inferior materials are quickly lost to premature failure and replacement costs.

Appropriate Thickness: Choose thickness based on your specific application, considering load requirements, frame spacing, and weight limitations.

Installation Quality: Proper installation with appropriate sealers and fasteners is just as important as material selection.

Maintenance Commitment: Factor in the ongoing maintenance requirements of different materials and finishes when making your selection.

Whether you’re building a new boat deck or planning to replace boat deck plywood, Pico Plywood offers premium marine-grade plywood solutions for every nautical project. Our extensive selection includes Okoume marine plywood, Baltic birch, and other specialized materials perfect for boat deck plywood applications.

Our expert team can help you select the right plywood for boat decking based on your specific needs, boat type, and budget requirements. From best plywood for jon boat deck projects to large vessel applications, we provide the quality materials and technical expertise needed for successful marine construction.

Contact Pico Plywood today to discuss your marine plywood boat decking project and discover why professional builders trust us for their most demanding applications. Visit our marine plywood section to explore our complete range of boat-building materials and accessories.

pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Strictly necessary cookies must always be enabled so that we can save your cookie setting preferences.

If you deactivate this cookie we will not be able to save your preferences. This means that each time you visit this website you will have to activate or deactivate cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable strictly necessary cookies first so we can save your preferences!